Handy Seafood’s Commitment to Environmental Responsibility & Operational Excellence

Responsible Sourcing & Fishery Improvement

NFI Crab Council

Handy Seafood, a founding member of the NFI Crab Council, plays a role in the organization’s mission to improve global crab fisheries. Since 2009, the Council has championed an industry-led approach, funding fishery improvement projects in six Asian countries. This initiative is primarily supported by a self-imposed tax on imported crab, which harnesses market demand to encourage responsible fishing practices and secure a future affordable supply of crab.

Responsibly Sourced Raw Materials (MSC, ASC, BAP & FIP)

We prioritize sourcing from certified sustainable fisheries and farms whenever possible. This includes surimi purchased from vendors who use fish from MSC-certified wild fisheries or ASC-certified farms, shrimp from farms participating in the Best Aquaculture Practices (BAP) program or ASC-certified farms, and crab meat from regions engaged in Fisheries Improvement Projects (FIPs).

Blue Swimming Crab & Mangrove Restoration

Our teams in Indonesia and Thailand are actively involved in restocking blue swimming crab populations and annual mangrove restoration projects. These efforts enhance crucial carbon sinks, absorbing CO2 and contributing to climate change mitigation.

Progress on Sustainable Non-Seafood Ingredients

We encourage our suppliers to source ingredients from more sustainable options whenever possible. While not all inputs are certified yet, we are committed to making continuous improvements in our ingredient sourcing practices; such as RSPO Palm oil, Soybean oil and paper packaging from

non-deforestation (FSC certified paper packaging).

Mangrove Tree Planting

Every year, over 100 of our employees in Thailand help plant mangrove trees. Mangroves provide essential breeding grounds and shelters for marine life. By reviving damaged mangrove forests, we are bolstering future populations of species such as the Mangrove Crab.

Local Sourcing Initiatives

We are increasing our use of local vendors for ingredients and packaging to help reduce transportation emissions and enhance supply chain efficiency.

Traceability

GS1 Barcoding

Handy Seafood utilizes GS1 barcodes across its products and packaging. This global standard significantly enhances supply chain efficiency, accuracy, and traceability from origin to consumer, streamlining logistics and improving food safety response capabilities.

FSMA Compliance

We are actively working towards compliance with FDA’s Food Safety Modernization Act (FSMA) traceability rule. We are building internal capabilities to enhance product traceability across our supply chain as regulations evolve.

Digital Tracking Systems

We are progressively implementing digital traceability tools, such as Trace Register™ , to track key data elements (KDE) like harvest location, methods, and critical tracking events (CTE). While full integration is still underway, we continue to strengthen our systems in alignment with industry-wide standards.

Packaging & Product Innovations

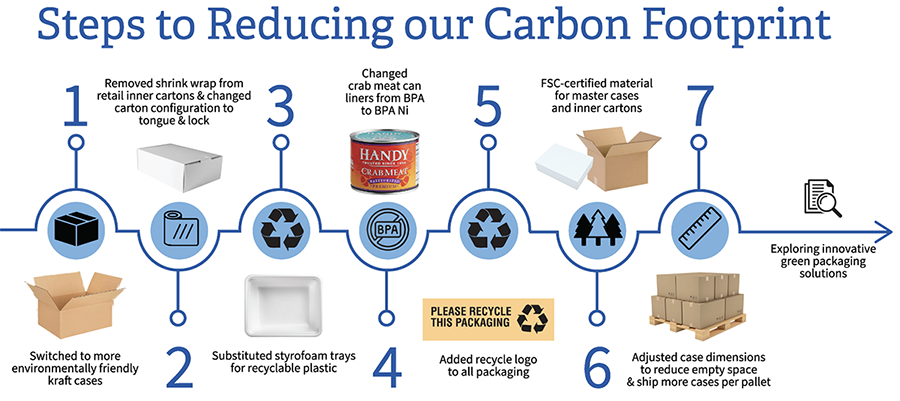

Reduced Single-Use Plastics

We’ve removed shrink-wrap from all retail cartons, significantly lessening our reliance on single-use plastics. This reduces energy consumption during production and disposal, lowering our overall carbon footprint.

Enhanced Recyclability

We encourage recycling of our laminated cartons and provide resources like TerraCycle for non-recyclable paper/cardboard. Promoting recycling reduces the need for virgin materials, saving energy and associated emissions.

Eco-Friendly & Certified Materials

We transitioned to more environmentally friendly kraft master cases, utilizing FSC (Forest Stewardship Council) certified materials. This ensures our paper products come from responsibly managed forests, supporting biodiversity and responsible forestry practices.

Recyclable Tray Conversion

We’ve replaced Styrofoam trays with recyclable plastic trays in our packaging. This change reduces reliance on slow-decomposing materials, increasing recyclability and lessening landfill waste.

Optimized Case Dimensions

By adjusting case dimensions to reduce empty space, we can ship more cases per pallet. This translates to fewer truckloads, lower transportation emissions, and increased logistical efficiency.

Plant-Based Crabless Cake

Handy Seafood has innovated with the introduction of a plant-based “Crabless Cake.” Offering plant-based alternatives significantly contributes to reducing the overall carbon footprint associated with food production, as these options typically have a lower environmental intensity compared to animal agriculture.

Product Quality & Food Safety

Audits and Certifications

Handy Seafood participates in a range of social and food safety audits to meet customer and market requirements. Our processing facilities undergo regular third-party reviews, with certifications that may include BRC (Brand Retail Consortium), HACCP (Hazard Analysis and Critical Control Points), and GMP (Good Manufacturing Practices), depending on the site. These efforts reflect our commitment to maintaining high standards in food safety, working conditions, and operational practices.

Quality Assurance (QA)

Handy employs full-time, dedicated QA teams at all processing plants. These teams meticulously oversee every step of production, ensuring the highest standards of safety, freshness, and taste for all our seafood products.

Gluten-Free Certification Organization

Handy Seafood’s gluten-free products are certified through GFCO.org, meeting the strictest gluten-free standards. The Gluten-Free Certification Organization (GFCO) is a program of the Gluten Intolerance Group of North America (GIG).

Community

Food Bank Donations

We proudly donate seafood products to hunger relief organizations across the communities we call home. This includes the Maryland Food Bank, as well as the Greater Boston Food Bank in New England.

Carbon Footprint